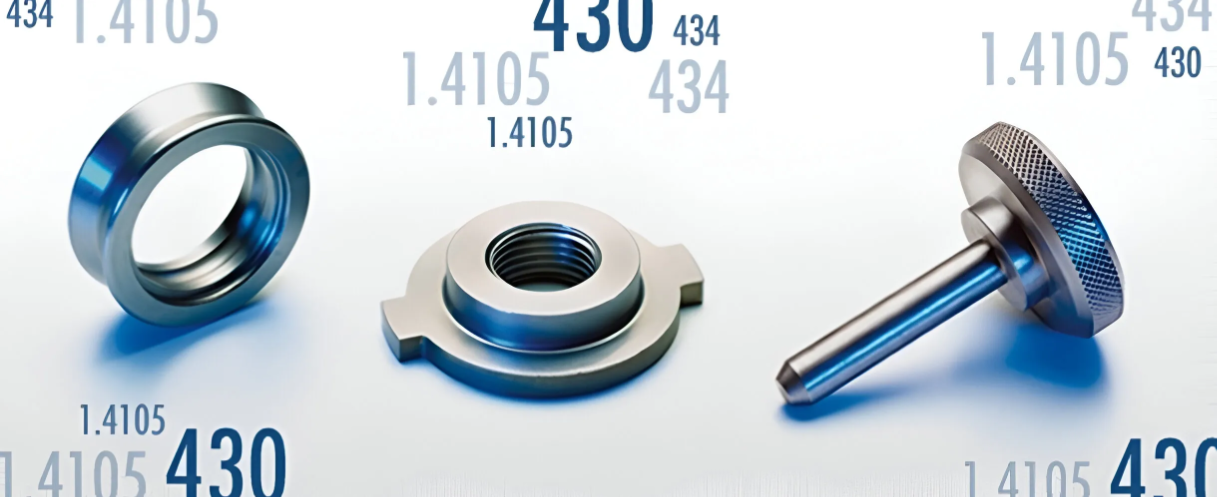

The ferritic stainless steels, which are characterized by a ferritic structure, cannot be tempered, but the mechanical strength characteristics can in any case be improved thanks to cold deformation or drawing. The chromium content ensures a good resistance to corrosion, further increased in the variety with the addition of molybdenum, while the addition of sulfur allows the machinability by chip removal to be improved. The steels of this category are often used in the white (appliances) sector, for the production of grills, and whenever a generic resistance to corrosion is required without very accentuated characteristics.